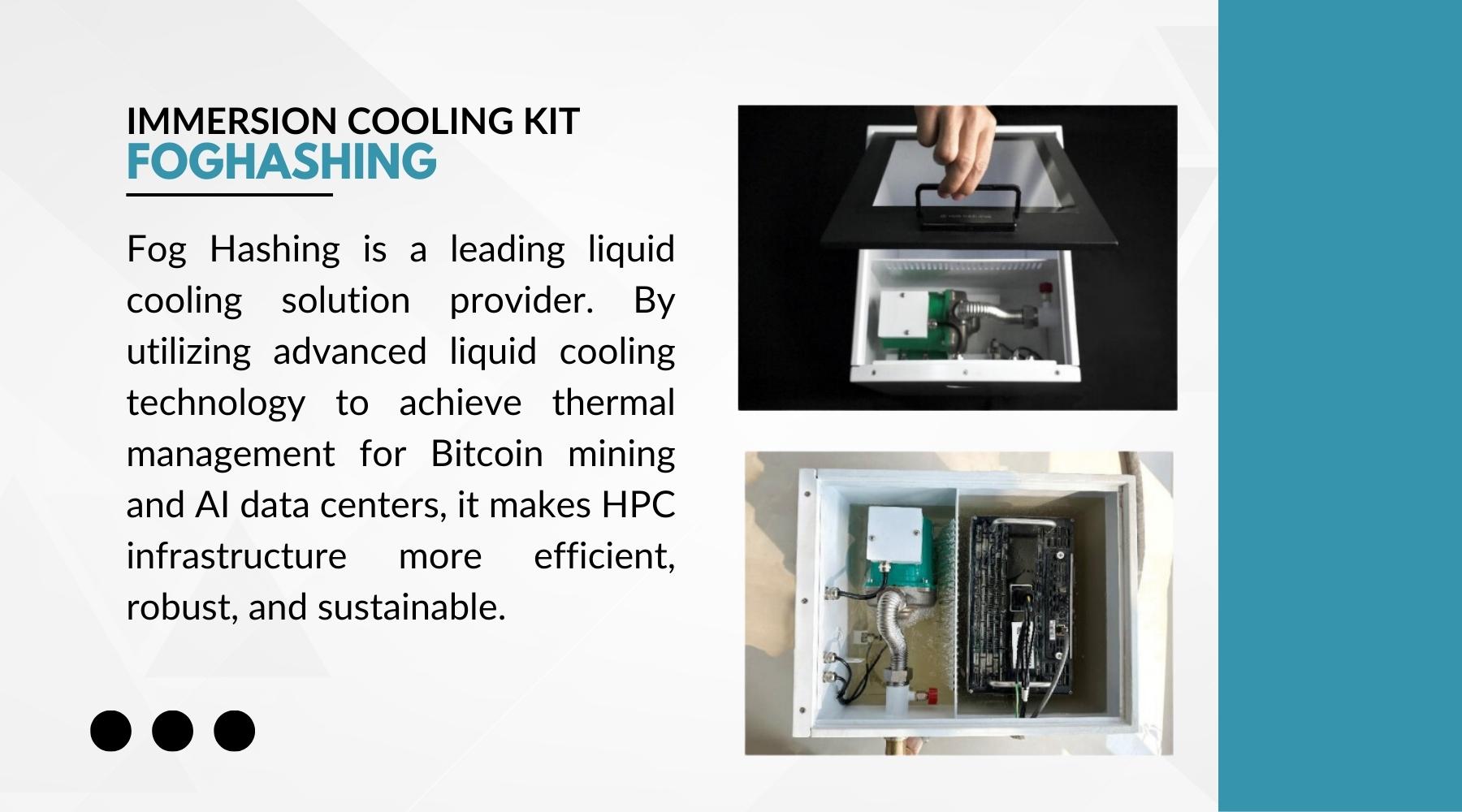

Fog Hashing C1 Immersion Cooling Kit

Designed For Asic Home Mining

• C1 is the all-in-one immersion cooling kit for home and office mining.

• Support one mining rig inside.

Quiet and Running Stable

Connected to work outdoors, the dry cooler exhibits minimal noise.

• Precise temperature control results in a low damage rate.

• Operating stably and long-term, with almost no maintenance.

Efficient Cooling and Overclocking

A much higher cooling efficiency than air cooling.

• Support 20-50% overclocking.

• Work well in extremely high-temperature environments.

Automatic Adjustment and status Monitoring

• loT sensors can help monitor the running status.

• Adjusting the PID algorithm enables automatic control of the inlet liquid temperature.

FogHashing collection

Asic Miner Silencer

ASIC Miner Silencer Superior Cooling Efficiency: Contrary to most recipes, which require cooling and storage in a cold room, this recipe does not r...

View full detailsLianli ASIC Water Cooling System

LIANLI ASIC WATER COOLING SYSTEM Revolutionize Your Home Mining with the Lianli ASIC Water Cooling System Unmatched Cooling Performance for Your Mi...

View full detailsAntminer Hydro Cabinet

Hydro Cooling Miner System for Antminer Hydro Series ASIC Miner Liquid Mining Cooling Solution Specifications for Antminer Hydro Cabinet 10 units 1...

View full detailswhatsminer Hydro Cabinet 12 & 20-Slot Rack

LIANLI hydro cooling cabinet for whatsminer hydro M53 M53S M53S++ M33S+ M33S++ miner heat dissipation solutions crypto mining cooling system Whats...

View full detailsFog Hashing C1 Asic immersion cooling kit

Fog Hashing C1 Immersion Cooling Kit Designed For Asic Home Mining • C1 is the all-in-one immersion cooling kit for home and office mining.• Suppor...

View full details